Mobile Saw J-001

1、 Product positioning: Multi scene manual cutting versatile tool

J-001 is an adjustable steel saw frame designed for straight cutting of materials such as metal, wood, and plastic, covering scenarios such as home repairs, small projects, and DIY crafts. Through the combination of an active structure and ergonomic design, we break through the limitations of traditional saw frames, such as limited adaptability and laborious operation, and achieve the goal of "one saw, multiple uses, high efficiency, and labor-saving".

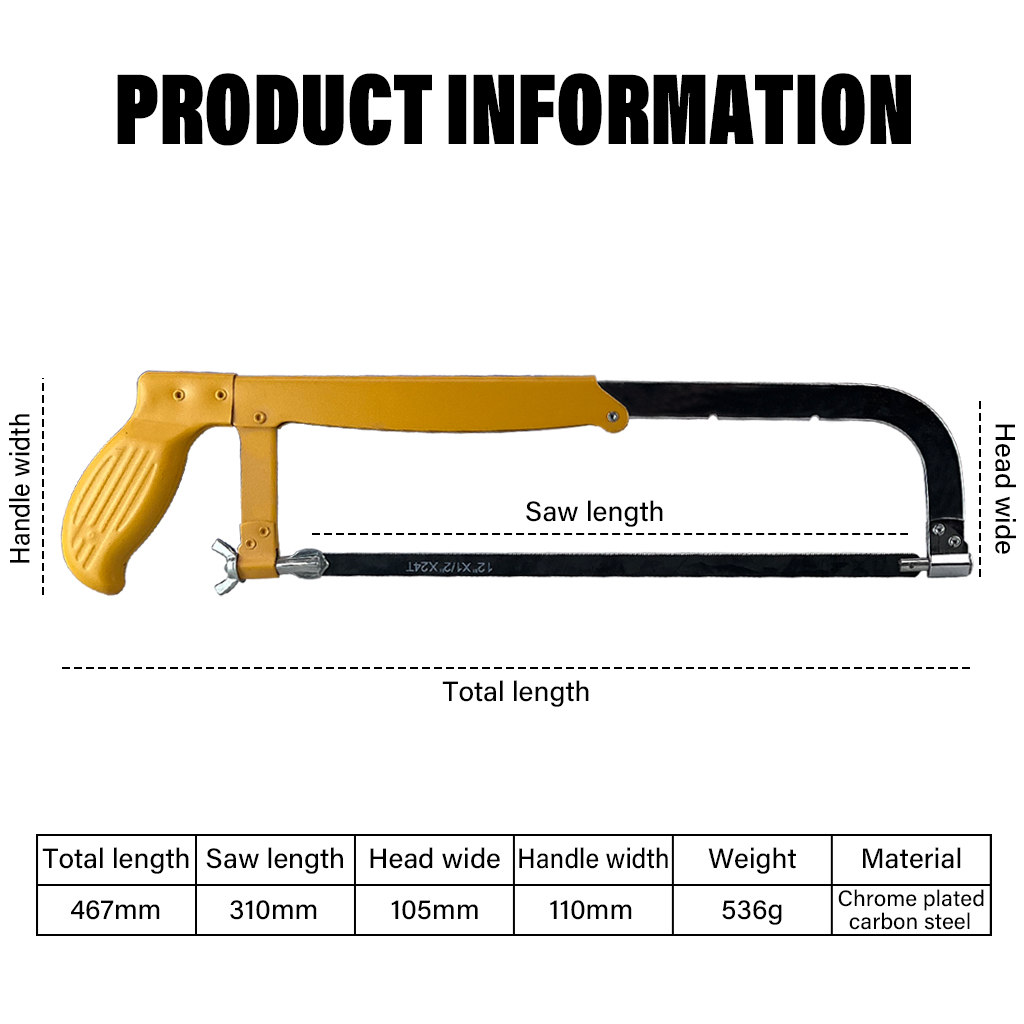

2、 Basic parameter table

Project Details Description

Model J-001

Weight 0.95kg (lightweight, long grip without burden)

Dimensions 46 × 12 × 3cm (moderate total length, flexible operation)

3、 Structural analysis: activity-based design, flexible response to diverse needs

Ergonomic anti slip handle:

Made of yellow engineering plastic material, with a curved contour that fits the palm and anti slip texture, it disperses pressure when held and reduces fatigue from long-term cutting; Smooth edges to avoid hurting hands.

Adjustable metal saw bow:

The saw bow is made of high-strength alloy steel, which is rust resistant and wear-resistant; Adjustable length design (suitable for 10-12 inch saw blades), short saw blades can handle narrow spaces, long saw blades improve cutting efficiency, and flexibly adapt to different scenarios.

Quick tensioning system:

Knob type tensioning device, one click locking of saw blade, ensuring stable and non slip cutting of saw blade; The tension is intuitively visible (the saw blade is in a taut state), preventing the saw blade from breaking and improving operational safety.

4、 Core functional highlights

Full material cutting adaptation:

Paired with corresponding saw blades (to be purchased separately), it can accurately cut:

Metal (fine toothed saw blade: pipes, profiles, screws, etc.);

Wood (coarse toothed saw blade: wood boards, wooden strips, furniture trimming);

Plastic (medium toothed saw blade: PVC pipe, acrylic board, model material).

Efficient operation design:

The movable saw bow supports quick replacement and length adjustment of the saw blade, reducing tool switching time; The metal saw bow has strong rigidity and small swing during cutting, ensuring the accuracy of straight cutting.

Durability and stability:

The metal saw bow has undergone surface rust prevention treatment, and the plastic handle is impact resistant and wear-resistant; The tensioning component is made of wear-resistant metal, which is not easy to deform or fail after long-term use.

5、 Typical application scenarios

Home maintenance: cutting metal water pipes, repairing wooden furniture, cutting PVC pipes/plastic boards, etc.

Small scale projects: cutting of scaffolding pipes, processing of steel structure supports, DIY woodworking (making storage racks and flower racks).

Handmade creation: cutting of model materials (wood/plastic), processing of metal crafts (iron, aluminum).

6、 Usage and Maintenance Guide

Selection and installation of saw blades:

Select saw blade based on material: metal → fine teeth, wood → coarse teeth, plastic → medium teeth;

During installation, ensure that the saw blade tip is facing the cutting direction (pushing forward is effective cutting), and tighten the knob until the saw blade is not loose.

Standardized operation:

Maintain a constant speed during cutting to avoid violent pushing and pulling (damaging the saw blade or affecting accuracy);

The narrow space can adjust the saw bow to the shortest distance, improving operational flexibility.

Daily maintenance:

Regularly clean the debris of the saw blade (to prevent tooth jamming), and apply rust proof oil to the metal saw bow;

Wipe the dirty handle with a damp cloth to avoid contact with corrosive solvents.